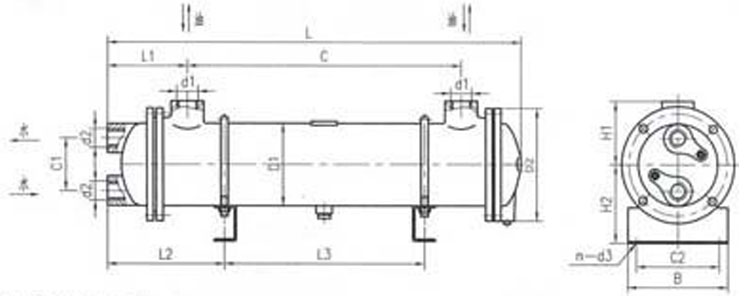

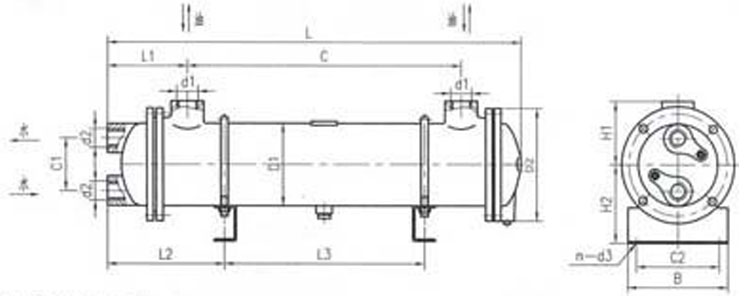

The tube heat exchanger heat exchange tubes can be arranged in an equilateral triangle or square on the tube sheet. The equilateral triangle arrangement is more compact, the degree of fluid turbulence outside the tube is high, and the heat transfer coefficient is large; the square arrangement is convenient for cleaning outside the tube, and is suitable for fluids that are prone to fouling. Each pass of the fluid through the tube bundle is called a tube pass; each pass through the shell is called a shell pass. In order to increase the fluid velocity in the tube, partitions can be provided in the tube boxes at both ends, and all the tubes are divided into several groups. This way the fluid passes through only part of the tube at a time, so it travels back and forth several times in the tube bundle. This is called multiple tube pass. Similarly, in order to increase the flow rate outside the tube, a longitudinal baffle may also be installed in the housing to force the fluid to pass through the housing space multiple times, which is called a multi-shell process. Multi-tube and multi-shell process can be used in conjunction. Because the temperature of the fluid inside and outside the tube is different, the temperature of the shell and the tube bundle of the heat exchanger is also different. If the two temperatures differ greatly, a large thermal stress will occur in the heat exchanger, causing the tube to bend, break, or pull away from the tubesheet. Therefore, when the temperature difference between the tube bundle and the shell exceeds 50°C, appropriate compensation measures must be taken to eliminate or reduce the thermal stress. According to the compensation measures used, the tube heat exchanger can be divided into the following main types:

The tube plate at both ends of the tube bundle of the 1 tube heat exchanger is integrated with the housing, and the structure is simple, but it is only suitable for the heat exchange operation when the temperature difference between the hot and cold fluids is not large and the shell process does not require mechanical cleaning. When the temperature difference is slightly greater and the shell pressure is not too high, an elastic compensating ring can be mounted on the housing to reduce the thermal stress.

2 The tube plate at one end of the floating head heat exchanger tube bundle can be freely floated, completely eliminating the thermal stress; and the entire tube bundle can be withdrawn from the housing, facilitating the mechanical cleaning and overhaul. Floating head heat exchangers have a wide range of applications, but their structures are relatively complex and their cost is high.

Each heat exchange tube of the 3 tube heat exchangers is bent into a U shape, and the two ends are respectively fixed on the same tube sheet and two lower areas, and are divided into two chambers by means of partitions in the tube box. This type of heat exchanger completely eliminates the thermal stress and the structure is simpler than the floating head type, but the tube process is not easy to clean. The heat exchange of strong corrosive fluids in chemical production requires shell-and-tube heat exchangers made of non-metallic materials such as ceramics, glass, polytetrafluoroethylene, and graphite. The heat exchange performance of this type of heat exchanger is poor, only for low pressure, low vibration, low temperature applications