Plate heat exchangers have been developed for quite a long time. From 1930 to 2018, "plate heat exchangers" have a history of 88 years. How much do you know about the knowledge, technology and technology of plate heat exchanger products? Following, from the development history of plate heat exchanger, product selection points, application fields and plate heat exchanger, this paper introduces the product knowledge of plate heat exchanger.

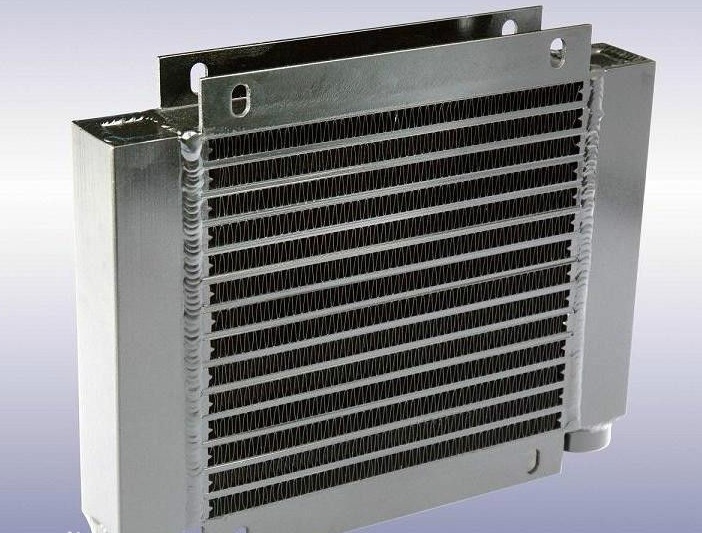

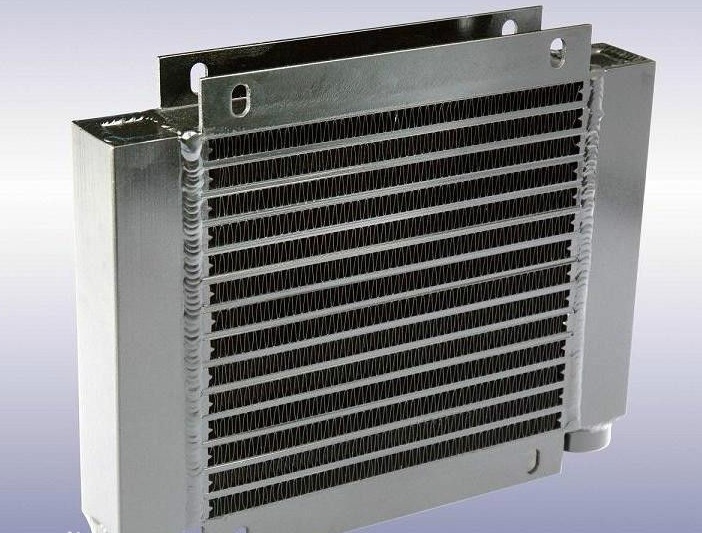

Vertical heat exchanger

Vertical heat exchanger

Development history of plate heat exchangers

Plate heat exchanger is a kind of high-efficiency heat exchanger made of a series of corrugated metal sheets. A thin rectangular channel is formed between plates, and heat exchange is performed through the sheet. Plate heat exchanger is an ideal equipment for heat exchange between liquid, liquid and steam. It has the characteristics of high heat transfer efficiency, small heat loss, compact and light structure, small floor area, wide application and long service life. Under the same pressure loss, the heat transfer coefficient is 3-5 times higher than that of tubular heat exchanger, occupying one third of the area of tubular heat exchanger, and the heat recovery rate can be as high as 90%.

There are two types of plate heat exchanger: frame type (detachable type) and brazing type. There are three types of plate: herringbone corrugated plate, horizontal straight corrugated plate and nodular plate.

In 1878, the German invented the plate heat exchanger and obtained the patent. By 1886, the Channel Plate Heat Exchanger was first planned by M. Malvazin of France and used for sterilization in wine production. In 1923, R. Seligman successfully planned a plate heat exchanger that could be produced in batches, starting with a combination of cast bronze plates, much like a plate-and-frame filter press. After 1930, there were only corrugated plate heat exchangers with stainless steel or thin copper plate restrictions. The plates of plate heat exchangers were sealed with gaskets near the plates. From then on, the plates of plate heat exchangers stepped into the modern corrugated plate restrictions with thin plates by the way of channel plates, which laid the foundation for the development of plate heat exchangers. It has a history of 88 years.

Plate heat exchanger has been widely used in various industries, and it is an efficient and compact heat exchange equipment. Its development has been more than 100 years ago. After extensive use and practice, we have deepened the superiority of the plate heat exchanger to know its uses. With the development of manufacturing skills, plate heat exchangers have become very important heat exchangers.

At the same time, the development of hydrodynamics and heat transfer has made an important contribution to the development of plate heat exchangers, and it is also the most important technical basis for the planning and development of plate heat exchangers. From the end of the 19th century to the beginning of the 20th century, Reynolds proved the existence of laminar and turbulent passenger flow by experiments, and proposed Reynolds number, which laid the foundation for the resistance and loss of activity. In addition, there are outstanding experts in fluid and heat transfer as well as Rayleigh Prandt Tsien Hsueshen Zhou Peiyuan.

Two, the main points of product selection

The control parameters of the plate heat exchanger are heat exchanger material, working pressure, design temperature and so on.

When choosing the heat exchanger, it is necessary to maximize the flow rate on the side with small heat transfer coefficient, and make the heat transfer coefficients on both sides of the two fluid heat transfer surfaces equal or similar, so as to improve the heat transfer coefficient. The temperature of the fluid heated by the heat exchanger shall be 10 degrees lower than the saturation temperature at the outlet pressure of the heat exchanger and shall be lower than the operating temperature of the pump used for secondary water.

The fluid containing sediment and dirt should be filtered into the heat exchanger.

When the plate heat exchanger is selected, the flow velocity at the interface of the fluid on the side of small temperature difference should not be too large, and the pressure drop should be satisfied.

For the case of large flow rate and small allowable pressure drop, the plate type with small resistance should be selected, on the contrary, the plate type with large resistance should be selected.

According to fluid pressure and temperature, choose detachable or electric welding.

It is not advisable to choose plates with too small veneer area, so as to avoid excessive number of plates, small flow velocity between plates and reduce heat transfer coefficient.

The heat transfer medium of the plate heat exchanger is not suitable for steam.

Three, application area

Plate heat exchangers have been widely used in metallurgy, mining, petroleum, chemical industry, electric power, medicine, food, chemical fiber, papermaking, textile, shipping, heating and other departments, can be used for heating, cooling, evaporation, condensation, sterilization, waste heat recovery and other situations.

Four. Vertical plate heat exchanger.

Guangzhou Qingli plate heat exchanger manufacturer provides you with comprehensive information on plate heat exchanger, so that you can fully understand more knowledge of plate heat exchanger product knowledge, technology, plate heat exchanger production process, production process, quality inspection, plate heat exchanger fault treatment and other product knowledge; at the same time, according to the requirements of customers. Professional customized plate heat exchanger products, tailor-made, one-to-one design services, free programs, so that you can easily choose plate heat exchanger products, escort you throughout the journey; advisory telephone: 020-28140958.